Are You Flying an Aging Aircraft? Be Aware of Metal Fatigue.

Needless to say, airplanes are expensive. Which means that airlines would prefer to keep planes in operation for a long time in order to make a return on investment.

But for the safety of pilots, passengers, and all citizens, it’s better to say goodbye to an aircraft early than too late.

The recent Boeing 767 crash raises this issue loud and clear. Although the causes are still unknown, the importance of inspections is put to the forefront.

But when exactly should an airplane be retired? And when is it okay to simply replace parts?

Pilots are not inspectors, and they’re not meant to be. But that said, pilots can sometimes notice issues with the plane before anyone else. That’s why pilots should be aware of metal fatigue.

Although many experienced pilots know what to be on the lookout for, let’s review the warning signs pilots should be know when flying an aging aircraft.

Metal Fatigue

Metal fatigue, the weakening of metal due to constant stress, is a legitimate concern for every individual component of the aircraft. These issues slowly eat away at an aircraft’s structural integrity and can eventually lead to a crash.

Which is why aircraft haul and wing integrity are supposed to be tested from time to time.

The Comet aircrafts began operation in the 1950s and are an example of how metal fatigue took down an entire type of aircraft. They stopped being operational when several of them crashed within a few months of each other. During one of the investigations, a portion of the cabin roof, specifically near the aerial window of the cockpit, was discovered.

Based on its shape and distance from the crash site, investigators concluded metal fatigue was the cause. And Comets were no longer deemed safe to fly.

Obviously, if a roof comes off during flight, this is a giant red flag on top of another giant red flag. But the point is that metal fatigue can cause structural damage. So if you see a crack or a group of tiny cracks that makes the metal look like frosted glass, this may be indicative of a much larger problem.

You can then alert an engineer who can run much more comprehensive tests.

Loud Noises

Sure, standard turbulence causes some shaking and rattling that unnerves passengers. But this is usually standard for any flight.

But if you’re exiting turbulence and the noises continue, you may have a problem. The extra stress from the turbulence may have increased the metal fatigue damage to a dangerous level. So consider making an emergency landing as soon as possible.

Any Interior Cracks

While inspections should always be taken seriously, sometimes important details are overlooked. Due to this, if you notice any bulging, split interior siding, or cracks, alert the proper authorities before takeoff.

Ongoing Prevention

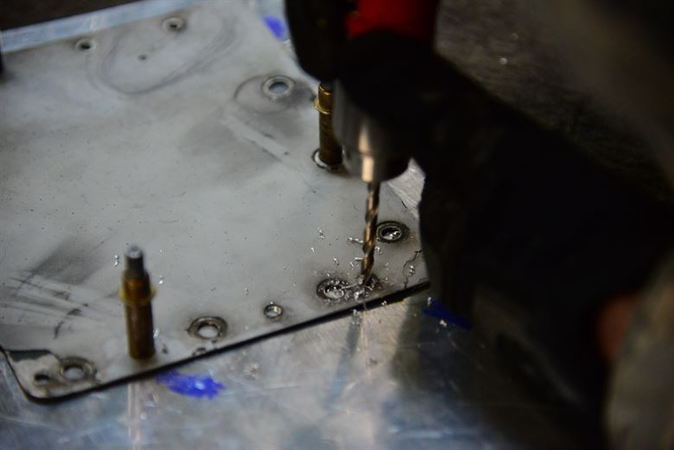

There are many tasks undergone to prolong the life of an aircraft. One of these routine maintenance operations is polish. Metal polish goes a long way in metal fatigue prevention.

Polish works as a layer of protection from the harsh elements. And it also reduces overall friction while a vehicle is in motion, which leads to less accumulated damage overtime.

That said, pilots can also take note of how shiny their aircraft is. If the exterior is looking dull the airplane may be long overdue for a polish update.

Thanks to FAA regulation and other precautions, airplane crashes due to using an older aircraft are less likely to occur. And although we do not have a set age for when a plane should be retired, we do know what to look for when flying an aging aircraft.

-

Airshare 07/22/2024

-

Alpine Air 07/18/2024

-

Atlas Air 07/17/2024

-

Piedmont Airlines 07/10/2024

-

SkyWest 07/09/2024

AIRLINE PILOT CENTRAL

AIRLINE PILOT CENTRAL